E-Commerce Packaging Automation: Why the E-CO Flex System Is a Game Changer

In the fast-paced world of e-commerce, packaging efficiency can make or break your fulfillment operation. As customer expectations for speed, sustainability, and precision continue to rise, businesses are turning to smarter automation solutions to stay competitive. Enter the E-CO Flex System—a revolutionary modular packaging system developed by IMA, integrated with IPG’s automatic Water Activated Taping heads and sustainable materials, available through Tishma Technologies.

What Is the E-CO Flex System?

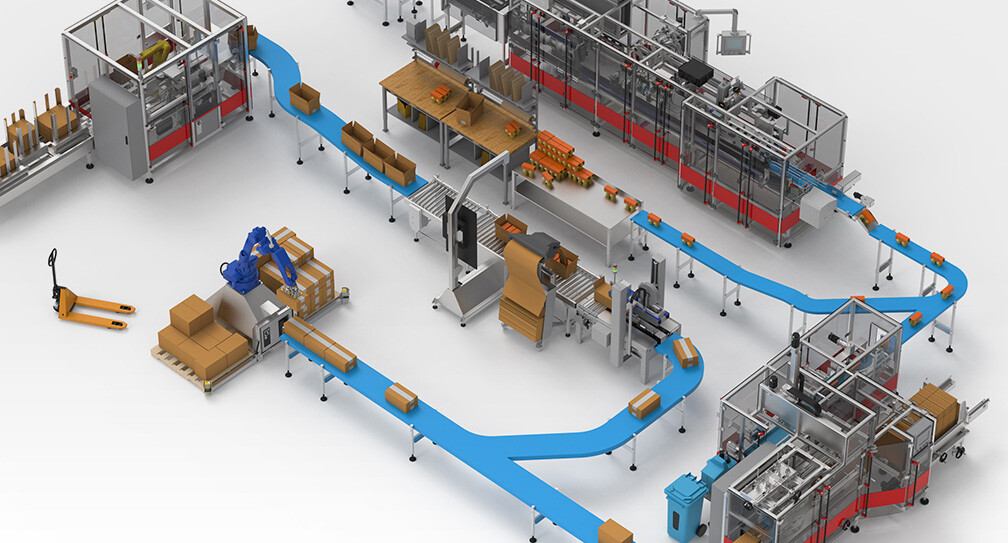

The E-CO Flex is a modular, fully automated random packaging system consisting of many flexible machine options to Form, Top Seal with WAT or PST, and even label corrugated cases replacing multiple traditional pack stations with a single, streamlined solution. It’s engineered specifically for e-commerce operations with a wide variety of on demand order sizes, quickly and efficiently.

Key Features of Vertical Cartoners:

-

-

Case Selection: May be manually selected by an operator on an HMI creating a que or Automatically with WMS, always providing the right-sized box when and where it’s needed.

-

Case Erecting: Automatically adjusts for each size on demand, erecting and sealing the bottom using IPG’s recyclable water-activated tape (WAT) or IPG’s Pressure Sensitive tapes.

-

Order Insertion: E-Co Flex can provide an integrated Operator pack station to place the products and any necessary void fill into the box.

-

Case Downsizing: allows the machine to cut and reduce case height minimizing shipping volume and dimensional weight when possible. A unique aspect in this process is automatic Tape re-alignment to the new folded flap position, ensuring a proper tape closure to each case.

-

Top Sealing: Automatically adjust to each case size, closing flaps applying WAT or PST tape to complete the package.·

-

This process not only improves throughput while less labor, but also reduces material waste and shipping costs—two major concerns for modern fulfillment centers.

Why It’s a Game Changer

-

Consolidates Multiple Packaging Steps

Traditional e-commerce fulfillment often involves separate stations for box selection, erection, packing, and sealing. The E-CO Flex combines all of these into one compact, efficient system—freeing up floor space and reducing labor requirements. -

Reduces Dimensional Shipping charges

By automatically downsizing cases to fit the contents, the E-CO Flex helps reduce dim weight charges, which can significantly cut shipping costs as soon as it’s installed!

-

Sustainability is Built In to the design

By applying IPG’s water-activated tape, which is not only recyclable but provides a stronger, tamper-evident seal compared to plastic alternatives. This aligns with growing consumer and regulatory demand for eco-friendly packaging. - Modular and Scalable

Whether you're a growing DTC brand or a high-volume fulfillment center, the E-CO Flex can scale with your needs. Its modular design allows for easy integration into existing lines and future expansion.

-

Operator-Friendly Design

Despite its advanced capabilities, the E-CO Flex is designed with simplicity in mind. Operators easily adjust to the HMI features, only needing to insert the product and void fill into a case—everything else is handled automatically.

Real World Impact

Companies that have implemented the E-CO Flex report:

-

-

Up to 50% reduction in labor costs

-

30% savings on shipping due to optimized box sizes

-

Improved order accuracy and throughput

-

Enhanced customer satisfaction with cleaner, more secure packaging

-

Final Thoughts

The E-CO Flex isn’t just another piece of machinery—it’s a strategic investment in the future of your e-commerce operation. By automating and optimizing every step of the packaging process, it helps businesses meet the demands of modern consumers while cutting costs and reducing environmental impact.

To learn more or request a quote, visit the E-CO Flex product page on Tishma Technologies.