Horizontal Cartoner For Plastic Tabs

One of our latest packaging automation projects is a horizontal cartoner that packs plastic tabs into a carton. This form of packaging solution is also often used for blisters, carded items, and similar products.

Our client was a company that manufactures rodent control products.

We came up with the following solution:

The TT-600S is a continuous motion side-load cartoner that can reach speeds up to 500 cartons per minute and this specific system loads three sizes of cartons at 85 cartons per minute. It is designed and built for the horizontal cartoning of plastic tabs in pre-broken folding cartons. This cartoning machine features a compact footprint that allows you to save on your floor space, a hot melt glue closing system, and an easy changeover between three carton sizes. At the same time, the simplicity and ergonomic design of this horizontal cartoner will enable every client to pack and prepare their products for shipping quickly and efficiently.

TT-600S Features

-Speeds up to 85 Cartons/Minute

-Compact Overall Footprint

-Handles 3 Different Carton Sizes

-Integrated Laser Date/Code Marking

-Quick Changeover and Easy Operation

-No product/No Carton and No carton/No Product Protocols

Operation Overview

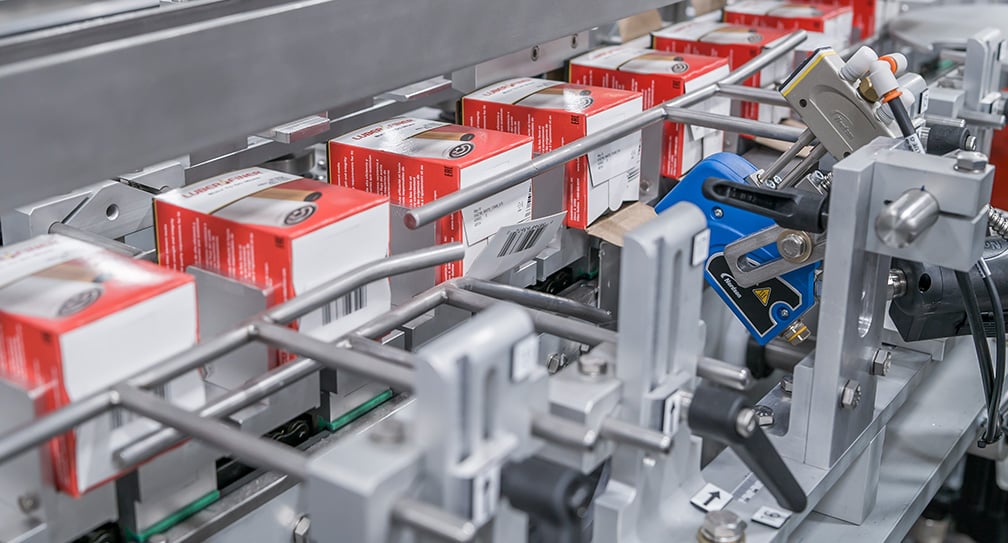

Completed products are discharged from the Assembly machine (not pictured in this post) and prepared for manual loading into the TT-600S Horizontal Cartoner. Products are manually placed into precision-milled article buckets. Flat cartons are stored in a 48” powered carton magazine with nickel-plated tubular steel frame, twin chain feed with shaft mounted pressure plate, and 1/8 H.P. drive motor with air clutch. Upon detection of the product, cartons are erected with the help of one high-speed gear-driven rotary carton feeder with vacuum cup carton placers. No product/No Carton and No carton/No Product protocols are included.

Once the products are manually loaded into the precision-milled article buckets, a static overhead confiner is utilized to ensure product introduction into the carton. A Nordson ProBlue 7 glue system with Surebead applies glue to bottom carton flaps. Carton flaps are closed using a series of stationary and mechanical plows. The system includes a melter unit, a hot melt dispensing gun mounted on adjustable brackets, and two 10-foot adhesive supply hoses. The glue system is placed inside the guards and can be refilled while the machine is running.

TT-600S also features a quick and easy changeover. Mechanical adjustments are performed by lead screws with easy-to-adjust knobs and tracked by calibrated scale references to facilitate easy set-up. The TISHMA calibrated scale reference helps to ensure quick and accurate changeover procedures and eliminates trial and error techniques. All adjustment stations are numbered for operator convenience.

TT-600 features an overall compact footprint, so you can rest assured it will fit your floor space. Reliable and portable with simple operation and a user-friendly interface, TT-600 will be up and running in no time, providing you with the best cartoning automation. Built from welded solid stainless steel with hinged cover panels and safety electrical interlocks, TT-600 is a powerful and efficient side-load cartoner that meets the highest standards with state-of-the-art simplicity.

Part of being a good packaging machine manufacturer is acknowledging that every client is special. We see the client’s specific demands as a challenge, and responding to that challenge is what makes us stronger and more experienced. If you are in a search of a packaging solution, don’t hesitate to contact us!