Mastering Packaging Line Integration - The OEM’s Advantage

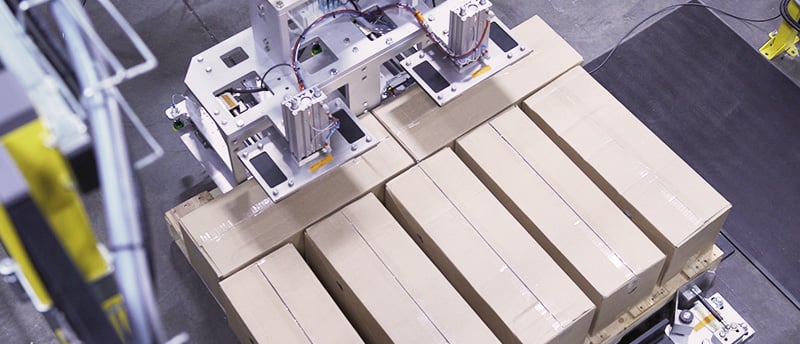

In the dynamic arena of secondary packaging, the harmonization of system components emerges as a pivotal factor for increasing efficiency, productivity, and operational uptime. Historically, this intricate process of integration was managed internally or through specialized third-party entities renowned for their expertise in line integration.

Presently, an increasing number of original equipment manufacturers (OEMs) specializing in secondary packaging are embracing integration as a core addition to their services, offering comprehensive end-of-line solutions. This strategic move is well-justified; their profound knowledge, established collaborations within the industry, the capability to tailor machinery for optimal line performance, and direct access to extensive testing environments position them as formidable candidates for this role.

Presently, an increasing number of original equipment manufacturers (OEMs) specializing in secondary packaging are embracing integration as a core addition to their services, offering comprehensive end-of-line solutions. This strategic move is well-justified; their profound knowledge, established collaborations within the industry, the capability to tailor machinery for optimal line performance, and direct access to extensive testing environments position them as formidable candidates for this role.

Exceptional Expertise

Exceptional Expertise

Packaging machinery OEMs distinguish themselves as adept integrators, courtesy of their deep-seated understanding of their equipment and its seamless integration with external devices. Their openness to incorporating machinery from various vendors to engineer the ideal solution for a particular task is noteworthy. Leveraging years of experience in constructing automation systems and engaging with clientele, OEMs adeptly navigate projects, grasping the underlying motivations, driving forces, and objectives. Through a comprehensive approach, they pinpoint project necessities and constraints, thereby proposing cost-efficient solutions and steering clients away from expensive oversights.

Streamlined Project Management

With manufacturers increasingly adopting LEAN methodologies, the pool of in-house experts capable of overseeing extensive packaging line integration projects is dwindling. OEMs, assuming responsibility for significant portions of a secondary packaging automation solution, alleviate the burden of micromanagement from clients. This method also mitigates potential disputes among integrators and suppliers, such as communication breakdowns, limited choice of vendors or equipment, and scheduling dilemmas. Moreover, OEMs overseeing safety compliance across the system ensures early identification of safety requirements in the design phase.

Expedited Project Completion

OEMs, utilizing a substantial portion of their apparatus in system designs, can directly influence lead times and synchronize schedules more effectively. Unlike external integrators who operate within client premises, most OEMs can assemble the entire system at their facility, enabling early detection and resolution of issues. Should modifications necessitate external assistance, OEMs can leverage their relationships with local fabricators, a convenience not available to onsite integrators dependent on regional vendors.

The Factory Acceptance Test (FAT) before dispatching the system allows clients to confirm optimal operation of the packaging line and implement any last-minute adjustments. This phase significantly cuts down startup times, highlighting the advantages of opting for a machinery builder for line integration tasks.

Enhanced Productivity

Enhanced Productivity

Entrusting a singular entity with the analysis and optimization of the entire application ensures consistent design throughout. Unified controls, interfaces, changeover methods, and components simplify the integration process, bolstering operational efficiency and productivity. This cohesive design approach facilitates a smoother installation and startup, allowing system-wide performance assessment rather than evaluating discrete components. Should issues arise, the design continuity enables swift diagnostics and problem-solving. For further technical support, clients can typically rely on the OEM integrator as their primary contact.

Superior Quality with Minimal Waste

The integrated system's common controls and standardized features significantly boost overall equipment effectiveness (OEE). A more reliable and smoother operation not only enhances output quality but also reduces resource wastage.

As pioneers in line integration, secondary packaging machine builders leverage their extensive industry experience and unique capabilities, solidifying their status as the preferred choice. Coupled with comprehensive lifecycle services, including parts and aftermarket support, OEM integrators deliver unparalleled value, potentially reducing the total cost of ownership significantly.

For detailed insights into Tishma Technologies' end-of-line integration capabilities and how we can support your objectives, please contact our team directly.