Stay Ahead of Downtime: The Power of Preventative Maintenance for Packaging Equipment

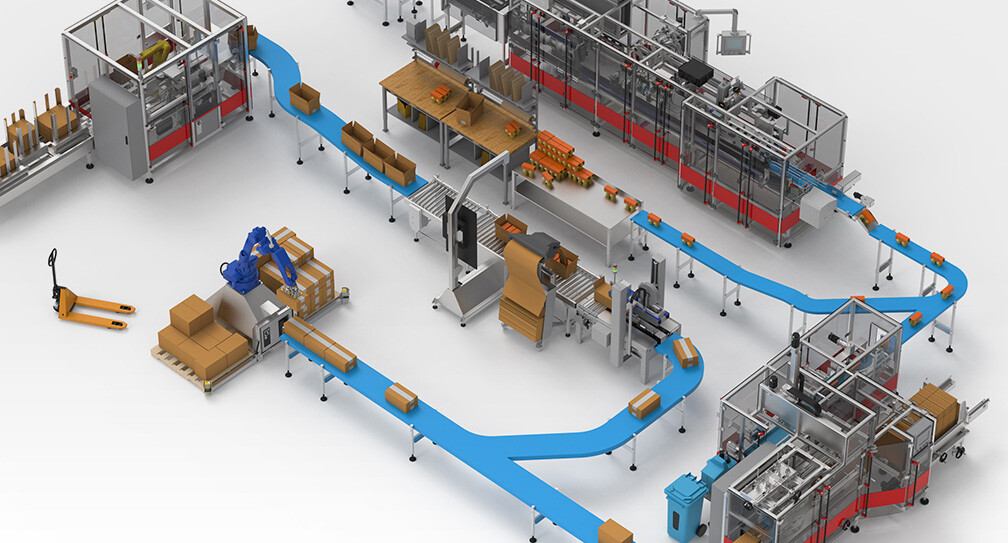

In the world of packaging automation, where efficiency, precision, and reliability are key, equipment downtime can significantly disrupt operations, impacting profitability. Proactive measures, such as preventative maintenance programs, play a pivotal role in ensuring your packaging line operates seamlessly. At Tishma Technologies, we understand this and offer tailored preventative maintenance solutions to keep your equipment running like clockwork.

Why Preventative Maintenance Matters

The manufacturing industry increasingly emphasizes preventative maintenance (PM), with 76% of companies recognizing its importance in minimizing long-term repair costs. Despite this, many businesses still rely on reactive repairs, leading to downtime, labor expenses, and costly and slow part replacements.

Proactive PM programs address these challenges, reducing reactive maintenance, extending machinery lifespan, and ensuring consistent output. Our programs focus on machine health audits, operator training, and regular servicing tailored to your specific packaging equipment

Services for Diverse Equipment

Services for Diverse Equipment

Tishma Technologies, supported by a team of over 300 skilled technicians ready for deployment at a moment’s notice across the United States, offers services for a wide range of packaging automation equipment:

-

- Cartoners (vertical and horizontal)

- Case Packers

- Case Erectors

- Tray Packers and Formers

- Palletizers

- Semi and Automatic Case Sealers

- Industrial Vision Systems

- Shrink & Stretch Systems, and more...

Tailored Preventative Maintenance Programs

We offer flexible PM programs, including Bronze, Silver, Gold, Platinum, and Titanium tiers. Each level provides varying service visit frequencies and cost benefits, such as discounts on parts kits and multi-year program savings.

Key Features:

Key Features:

-

- Pre-scheduled service visits.

- Machine health checks and component reviews.

- Operator training to optimize equipment use.

- Customizable reports to analyze service performance.

The ROI of Maintenance Programs

For operations managers and plant engineers, the focus is clear: maximizing ROI. Preventative maintenance translates to reduced downtime, improved safety, and sustained machine efficiency. The costs of reactive repairs, averaging 30-50% of maintenance expenses, underscore the value of proactive investment.

Partnering for Packaging Excellence

Our preventative maintenance solutions aren’t just about fixing machines; they’re about building strong partnerships. With centralized service call centers and rapid parts availability, Tishma Technologies is committed to your success.

Ready to Optimize Your Packaging Lines?

Discover how our preventative maintenance programs can enhance your packaging operations. Contact us at tishmaservices@itape.com to schedule a consultation and start reaping the benefits of proactive maintenance today.

By investing in robust PM solutions, your packaging automation systems can achieve unparalleled reliability, enabling you to focus on what matters most: delivering excellence to your customers.