Streamlining Success: Optimizing Your Packaging Line with Tishma Technologies

Optimizing a packaging line is a multifaceted journey that entails not only integrating and upgrading machinery but also considering a broad spectrum of factors including operational efficiency, total cost of ownership (TCO), and return on investment (ROI). Packaging line optimization is not just about the machinery; it’s a holistic endeavor that requires attention to soft factors such as employee skill sets and training, as well as hard factors like machine efficiency and the specifics of packaging materials.

Holistic Approach to Optimization

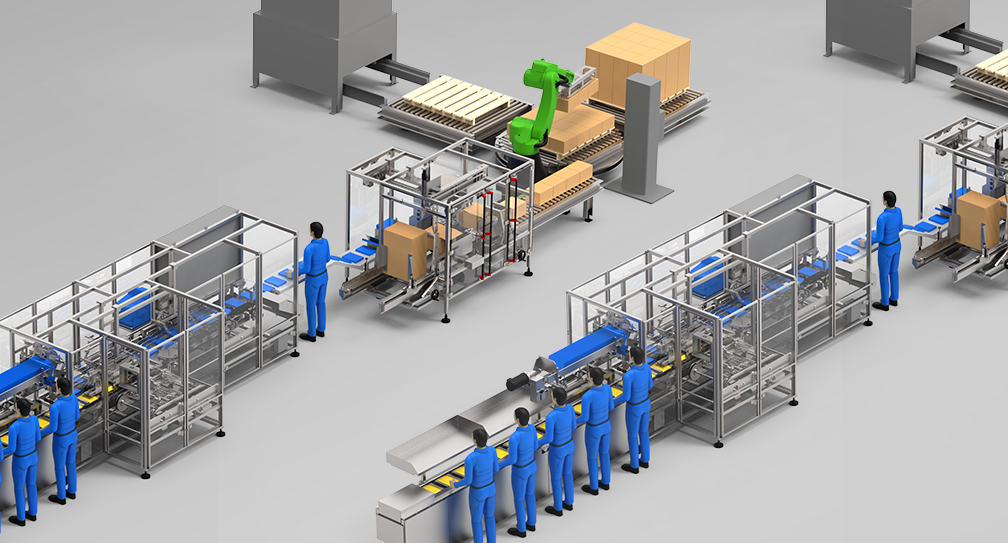

A common thread among packaging experts is the importance of a holistic view. This begins with engaging with the operational staff to understand the ground realities and extends to ensuring a comprehensive understanding of the machinery and materials in use. For instance, integrating line operations to ensure smooth communication between different components can dramatically enhance efficiency. This calls for a blend of high-quality machinery, such as those offered by Tishma Technologies, and strategic planning.

A common thread among packaging experts is the importance of a holistic view. This begins with engaging with the operational staff to understand the ground realities and extends to ensuring a comprehensive understanding of the machinery and materials in use. For instance, integrating line operations to ensure smooth communication between different components can dramatically enhance efficiency. This calls for a blend of high-quality machinery, such as those offered by Tishma Technologies, and strategic planning.

Key Variables in Packaging Line Optimization

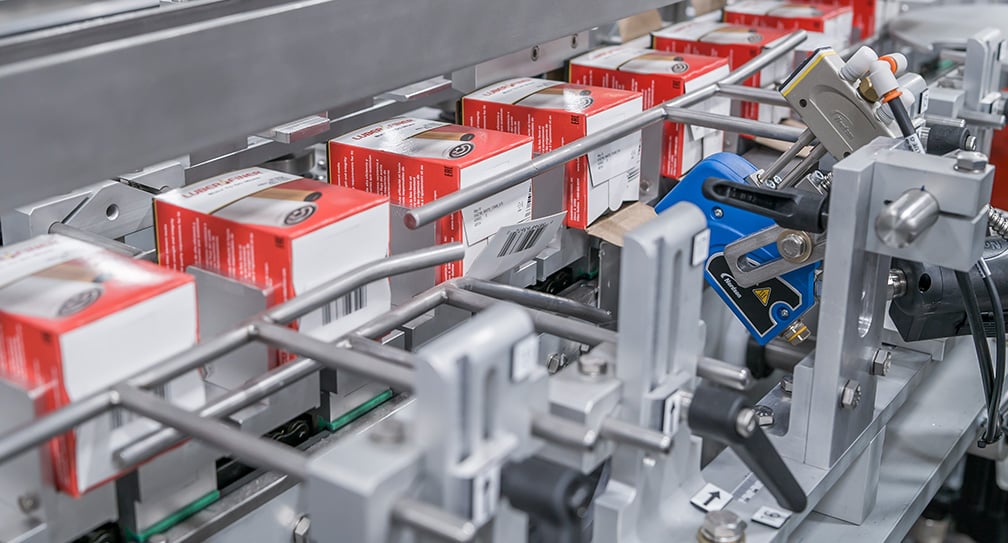

Speed, cost, downtime, automation, and compact floor space are critical variables in the optimization process. For Tishma Technologies, addressing these variables means offering advanced end-of-line solutions like cartoners, case packers, and palletizers that designed and built for minimal downtime, compact footprint, and maximum efficiency. These solutions directly address the concerns of procurement managers, operations managers, and engineering teams by ensuring reliability, reducing waste, and optimizing the use of floor space.

Incorporating Advanced Technologies

Incorporating Advanced Technologies

Adopting Industry 4.0 technologies is another pillar in the optimization process. By integrating smart manufacturing technologies, Tishma Technologies ensures that its machinery is not only efficient but also future-proof. This approach aligns with the advice from experts who emphasize the importance of standardization, automation, and digital technologies to improve overall equipment effectiveness (OEE) and reduce total cost of ownership (TCO).

Maximizing Operational Efficiency

To further enhance operational efficiency, Tishma Technologies focuses on providing equipment that is easy to operate and maintain, thus reducing downtime and labor costs. This is particularly important in industries where quick turnarounds are essential, and any delay can have significant financial implications.

The Tishma Technologies Advantage

Tishma Technologies stands at the forefront of packaging line optimization by offering a range of machinery that addresses the key concerns of the buying center, from the project managers to the C-level executives looking for ROI, and the engineering teams concerned with machine efficiency and technology quality. By focusing on providing integrated, automated, and efficient packaging solutions, Tishma Technologies plays a crucial role in enhancing the productivity and profitability of packaging lines across various industries.

Packaging line optimization is a comprehensive process that demands attention to both machinery and operational practices. With its focus on innovation, reliability, and efficiency, Tishma Technologies continues to be a key partner for businesses looking to enhance their packaging operations. We’re here to help solve your packaging challenges, let’s address your packaging line challenges.