Tetristack – Robotic Pail Palletizer

Modern robotics keep revolutionizing the way goods are stored and transported, and palletizing is one of the essential applications of robots in the packaging industry.

Tishma Technologies’ Tetristack pail palletizer is a robotic packaging solution designed to stack and arrange pails or other cylindrical containers onto pallets with precision and speed, ensuring that they are securely held in place for storage or transportation. It features Fanuc M-410iC/185 robot with an end-of-arm tool that can handle buckets up to 70lbs.

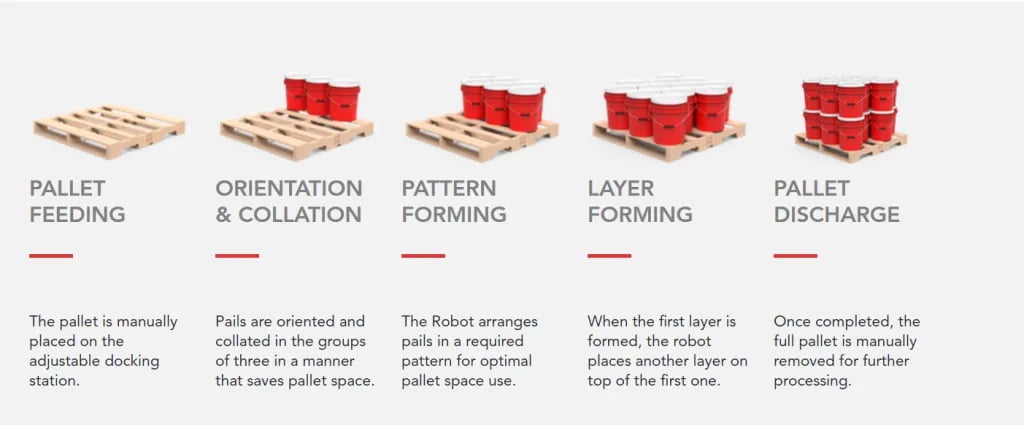

SEQUENCE OF OPERATION

One infeed conveyor delivers the pails to the orientation station. Pails are oriented and collated in groups of three to save pallet space. The pallet is manually placed on one of two adjustable docking stations. The robot places the pails on the pallet, arranging them in the required pattern. The pails are stacked in two layers. The full pallet is manually removed for further processing.

FEATURES:

Speed: Tetristack Palletizer can stack pails onto pallets at a higher speed, allowing for more efficient production and faster order fulfillment.

Flexible Pail Handling: Tetristack palletizer can handle a variety of pail sizes and shapes, making it a versatile solution for different industries. This particular model can handle two pallet sizes, allowing users to arrange pails in multiple patterns.

Precise Palletizing: Tetristack palletizer uses advanced sensors and algorithms to ensure that each pail is precisely positioned on the pallet, reducing the risk of damage during storage or transportation. Tetristack features the Multi-Pattern Pail Orientation system, allowing users to choose how the pails will be arranged on the pallet to maximize the pallet-space use. The pail orienting and collating station forms the groups of three pails, arranging them under a specific angle so the canister handles don’t collide. Recipe formulation and adjustments are performed via the Fanuc Teaching Pendent. The Robot picks and places pails into one of two available patterns: 3x3x2 and 3x4x2. Besides pails, this orienting system can also handle buckets, drums, and other cylindrical containers.

Space-Saving Design: Tetristack palletizer has a compact design, which allows it to fit into tight spaces, making it ideal for facilities with limited floor space.

GENERAL OPTIONS: Slip/tier-sheet rack; Zero pressure product in-feed conveyor. Full line integration service

PRODUCT IN-FEED OPTIONS: Case erection, Case loading, Case sealing, Case closing, Labeling, Vision inspection, Check weighing, Rejection

END EFFECTOR OPTIONS: Pail tool, Clamp tool, Fork tool, Case/bag tool, Vacuum tool

PALLET OUT OPTIONS: Buffer conveyors and Stretch wrapper

PALLET IN-FEED OPTIONS: Pallet dispenser

Tetristack palletizer can complete tasks that would typically require multiple workers, reducing the need for manual labor and associated labor costs. It allows you to save time and reduce the labor and effort needed to complete the task.

Use Tetristack Palletizer to increase efficiency, accuracy, and safety in your operations while reducing labor costs and increasing overall productivity.