The Project Manager's Blueprint to Successful Packaging Line Integration

In the bustling world of packaging operations, project managers are the maestros, orchestrating every detail from the initial concept to the full-scale execution of packaging line integration. This guide is designed to navigate you through the complexities of integrating new packaging systems into existing operations. Drawing upon the expertise of Tishma Technologies, one of the leaders in packaging automation machinery, we delve into milestones, common challenges, and strategies for seamless execution, ensuring that your project not only meets but exceeds expectations.

Understanding the Landscape

Before diving into the intricacies of packaging line integration, it’s crucial to grasp the broad spectrum of considerations that will guide your project to success. This includes understanding the needs and concerns of various stakeholders within the buying center—ranging from C-level executives focused on ROI to operations personnel concerned with efficiency and uptime. Aligning the integration project with these varied interests is your first step toward a successful outcome.

Milestones to Monitor

Project Kick-off: Initiate with a comprehensive project plan, detailing timelines, budgets, and specific goals.

Stakeholder Alignment: Ensure all parties, from executives, engineers, and operators, are on board and understand their role in the integration.

Stakeholder Alignment: Ensure all parties, from executives, engineers, and operators, are on board and understand their role in the integration.

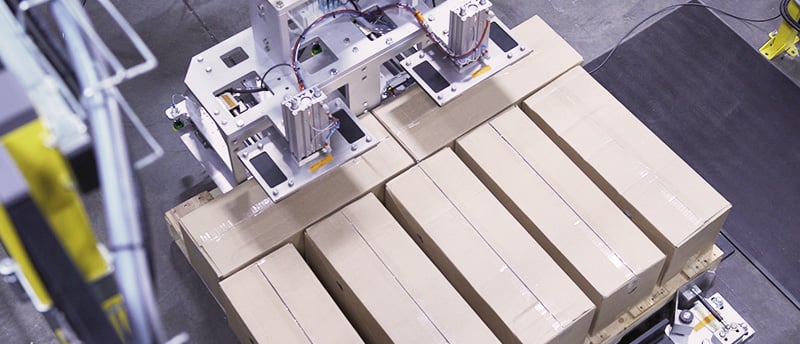

Technology Selection: Choose the right machinery—be it a cartoner, case packer, or palletizer—that fits the operational needs and meets efficiency goals.

Design and Engineering: Collaborate with designers, engineers, and procurement to ensure the equipment is tailored to your specific packaging lines.

Assembly: The assembly phase, where the components of the packaging solution are put together, is the lengthiest portion of the timeline. Keep regular communication to ensure the project stays on track.

Factory Acceptance Test (FAT) : Assess a product's functionality, performance, and quality at the supplier's site before shipment, ensuring it meets all specifications. Conducted with customers present, FAT provides a hands-on learning experience about the system or product's operation.

Shipment: The considerable dimensions of packaging machinery make transportation a complex task. It's crucial to select a reliable freight provider who ensures safe delivery without damage and at a fair price.

Installation and Testing: Install the new systems and conduct thorough testing to guarantee operational efficacy.

Site Acceptance Test (SAT): Represents the final step in the equipment qualification process. This phase involves a comprehensive series of tests conducted on the machinery at the customer's site. The purpose of the SAT is to provide definitive proof that the equipment or system has been transported and delivered without any damage or degradation, ensuring it is in prime condition for operation.

Training and Onboarding: Equip your staff with the necessary knowledge and skills to operate the new machinery effectively.

Go-live and Monitoring: Launch your integrated packaging line, closely monitoring performance and keeping up with maintenance service schedules and technical support.

Overcoming Common Challenges

Budget Constraints: Early planning and clear communication with procurement managers can help align expectations and manage costs effectively.

Technology Compatibility: Ensuring the new machinery integrates seamlessly with existing systems is paramount. Engage with engineers early to address compatibility issues.

Operational Disruption: Plan for minimal downtime by scheduling major integration steps during off-peak hours or maintenance periods.

Change Management: Prepare your team for change with comprehensive training sessions and open communication channels to address concerns.

Seamless Execution Strategies

Seamless Execution Strategies

Vendor Collaboration: Work closely with your machinery manufacturer, such as Tishma Technologies, to leverage their expertise in designing and building custom solutions.

Project Management Excellence: Utilize project management tools and methodologies to keep the project on track and stakeholders informed.

Continuous Improvement: Adopt a mindset of continuous improvement, using feedback from the operations team to fine-tune processes and machinery performance.

Safety and Compliance: Prioritize safety and regulatory compliance throughout the project, ensuring that all new equipment meets industry standards.

Conclusion

Integrating new packaging machinery into an existing operation is a complex but rewarding endeavor. By understanding the needs of your organization, planning meticulously, and employing strategic execution methods, you can ensure a smooth integration process. The key to success lies in effective project management, stakeholder engagement, and choosing the right technology partners. With Tishma Technologies by your side, you’re well-equipped to navigate the challenges and opportunities of packaging line integration, propelling your operations toward increased efficiency and productivity. Get in touch with our team to find out how we can solve your packaging line challenges.